Features of torque actuator

Based on the opinions of each user, the Torque Actuator “Type 4 and Type 5” pursues “compact”, “low air consumption” and “light weight” based on the conventional type. , An improved new product. It is an epoch-making structure that uses air pressure as the operating medium and immediately converts the vertical movement of the piston cylinder into the left-right rotational movement of the shaft.

It was originally developed as a valve drive,

● Stable and large output (same output for both braking and running)

● Long life

● Light weight

● Compactness Due to

its functions such as <br>, it has been adopted in all machine / industrial machines and automation equipment that need rotation function as well as valve use. We are.

Unlike conventional cylinders that change rotation by gears or levers, friction resistance is significantly reduced by six bearings, and the operating pressure is converted to torque as it is, so it is very efficient and large output can be obtained. In addition, each part is designed to be easy and affordable, maintaining high performance for a long time.

The material is made of aluminum alloy, so no excessive load is applied during piping and installation.

Since the piston is moved up and down by applying operating air to rotate the shaft, the width is smaller than that of a horizontal cylinder, and it is extremely small and requires less installation area to obtain the same output than other cylinders.

The cylinder uses a unique lubricant whose inner surface becomes a film. Since the friction resistance is very low, it can withstand continuous operation for a long time as it is and there is no need to constantly lubricate, so no oiler is required.

The connection between the torque actuator and the work piece can be easily installed on any product directly or by installing a stand in the middle. Therefore, assembly time is shorter than other cylinders, and it is easy to remove for maintenance and inspection. In addition, it is resistant to vibration, and there is no deterioration in performance and no loosening of the joints for 4G.

Torque characteristic graph

AT4 torque actuator

The AT4 is the basis of another type and is most widely used for valves and all equipment.

The spring type can automatically change the rotation angle in the event of an unexpected accident such as failure of the operating pressure piping and compressor, and is often used for emergency shutoff of ball valves, butterfly valves, dampers, etc. Used.

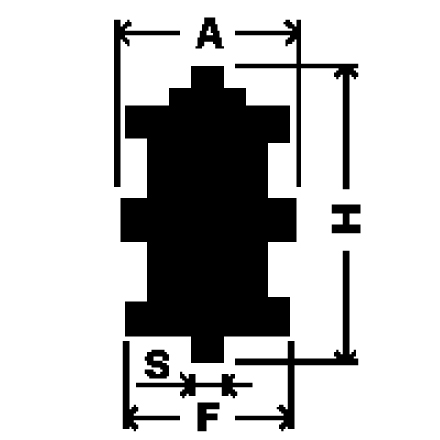

AT4 torque actuator standard specifications

| AT4 standard type | AT4S spring type | |

|---|---|---|

| model | AT4-50 to AT4-300 | AT4S-50 to AT4S-300 |

| rotation angle | 90 ° | |

| Service temperature | -15 ℃ ~ + 80 ℃ | |

| Operating pressure | 0.05MPa ~ 0.7MPa | Standard 0.4MPa |

| Direction of rotation | Press from top-turn left | Pressing from the bottom-rotating left |

| Actuation | Double acting | Reverse operation (single operation) |

* Install solenoid valves, limit switches, regulators, positioners, manual devices, angle adjustment stoppers, etc.

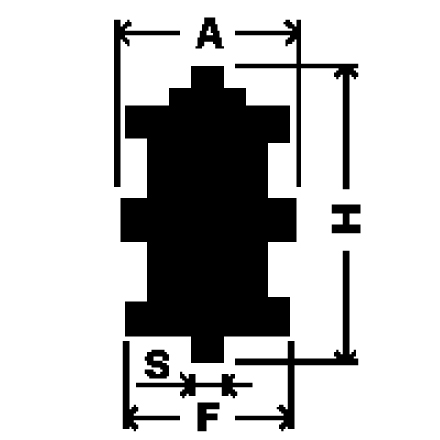

| size | S | F | H | A | Piping Connection RC | |

|---|---|---|---|---|---|---|

| AT4 | AT4S | |||||

| 50 | 9.5 | 85 | 170 | 218 | 90 | 1/4 |

| 65 | 12 | 110 | 211 | 283 | 111 | 1/4 |

| 80 | 15 | 130 | 255 | 331 | 134 | 1/4 |

| 100 | 19 | 160 | 305 | 398 | 168 | 1/4 |

| 120 | 23 | 182 | 359 | 484 | 196 | 1/4 |

| 150 | 28 | 235 | 451 | 573 | 238 | 3/8 |

| 180 | 34 | 274 | 548 | 675 | 278 | 3/8 |

| 220 | 41 | 340 | 658 | 808 | 356 | 1/2 |

| 250 | 48 | 270 | 751 | 947 | 390 | 1/2 |

| 300 | 56 | 450 | 947 | 1249 | 430 | 1/2 |

AT5 torque actuator

Spring type is mainly used for emergency shutoff of butterfly valves etc.

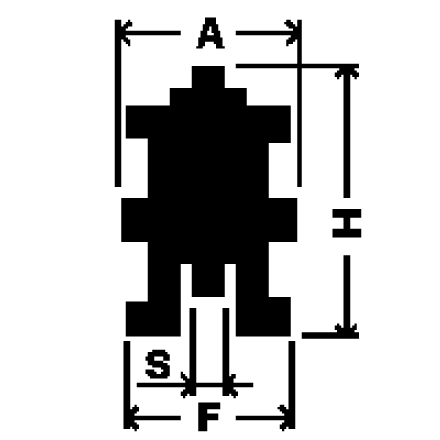

AT5 torque actuator standard specifications

| AT5 standard type | AT5S spring type | |

|---|---|---|

| model | AT5-80 to AT5-300 | AT5S-80 to AT5S-300 |

| rotation angle | 90 ° | |

| Service temperature | -15 ℃ ~ + 80 ℃ | |

| Operating pressure | 0.05MPa ~ 0.7MPa | Standard 0.4MPa |

| Direction of rotation | Press from top-turn left | Pressing from the bottom-rotating left |

| Actuation | Double acting | Reverse operation (single operation) |

| size | S | F | H | A | Piping Connection RC | |

|---|---|---|---|---|---|---|

| AT5 | AT5S | |||||

| 80 | 15 | 100 | 255 | 331 | 134 | 1/4 |

| 100 | 19 | 125 | 294 | 387 | 168 | 1/4 |

| 120 | 23 | 140 | 351 | 476 | 196 | 1/4 |

| 150 | 28 | 162 | 421 | 543 | 238 | 3/8 |

| 180 | 34 | 194 | 519 | 646 | 278 | 3/8 |

| 220 | 41 | 238 | 610 | 760 | 356 | 1/2 |

| 250 | 48 | 270 | 695 | 891 | 390 | 1/2 |

| 300 | 56 | 324 | 877 | 1179 | 430 | 1/2 |

ATR type torque actuator

ATR type standard specification for torque actuator

| ATRF 150 ° rotation type | ATR 180 ° rotation type | |

|---|---|---|

| model | ATRF-50 to ATRF-220 | ATR-50 to ATR-180 |

| rotation angle | 150 ° | 180 ° |

| Service temperature | -15 ℃ ~ + 80 ℃ | |

| Operating pressure | 0.05MPa ~ 0.7MPa | |

| Direction of rotation | Press from top-turn left | |

| Actuation | Double acting | |

* Install solenoid valves, limit switches, regulators, positioners, manual devices, angle adjustment stoppers, etc.

| size | S | F | H | A | Piping Connection RC | |

|---|---|---|---|---|---|---|

| AT5 | AT5S | |||||

| 50 | 9.5 | 85 | 268 | 300 | 90 | 1/4 |

| 80 | 15 | 130 | 404 | 458 | 134 | 1/4 |

| 100 | 19 | 160 | 490 | 556 | 168 | 1/4 |

| 120 | 23 | 182 | 582 | 664 | 196 | 1/4 |

| 150 | 28 | 235 | 715 | 814 | 238 | 3/8 |

| 180 | 34 | 274 | 880 | 1000 | 278 | 3/8 |

| 220 | 41 | 340 | 1056 | – | 356 | 1/2 |